Standard processes

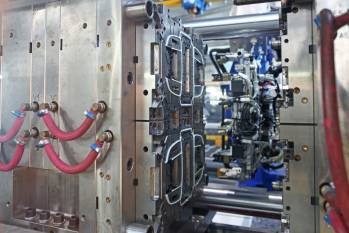

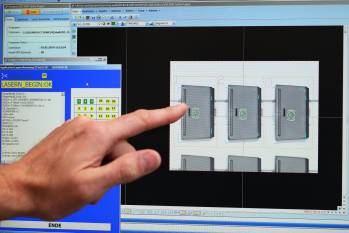

Injection moulding

We use state-of-the-art injection moulding machines to produce our raw parts according to the specifications of our customers. We can meet almost all customer requirements, from simple 1-component parts to complex multi-component solutions using a variety of plastics.

Electroplating

Our fully automatic electroplating plants plate the plastic mouldings using the latest REACh-compliant technologies and environmental requirements. The same standards apply at all BIA locations.

Final inspection

The components produced by BIA are 100% visually inspected prior to despatch to the customer. The tests are carried out in accordance with the standards of the automotive industry. Tests and post-treatments according to special customer specifications can also be arranged.

Special processes

Painting system

At the BIA location in Solingen we offer in addition to electroplated “real metal” surface finishes also painted plastic components.

Selective coating

Using various processes, such as laser technology, printing with a protective lacquer or by 2-component injection moulding, components can be selectively chrome plated. Specific areas of the component surface thus remain chromium-free and translucent.

Plating on polyamide

In addition to the standard ABS or ABS / PC, components made of polyamide are chrome-plated in identical finishes at the Nitra site. This more stable material is ideal for components subject to high mechanical stress, such as door handles.